Industrial Epoxy Floor Maryland

In an industrial setting, your floors need to withstand the heaviest demands, from machinery and forklift traffic to chemical spills and heavy foot traffic. At Garage Floor Coatings of Maryland, we specialize in industrial epoxy floor installations that provide the durability and low-maintenance properties your business requires. Whether you’re managing a manufacturing plant, warehouse, or distribution center, our epoxy flooring solutions are designed to handle the harshest environments while maintaining their integrity and appearance.

Unveiling the Artistry: Epoxy Flooring Solutions for Maryland Spaces

Why Choose Industrial Epoxy Flooring?

When it comes to industrial environments, the demands on flooring are intense, and traditional options often fall short. Epoxy flooring provides an advanced solution that not only meets these rigorous demands but also exceeds them. The combination of durability, resistance, and cost-effectiveness makes epoxy the go-to choice for industrial spaces.

- Built for Extreme Conditions: Epoxy flooring is specifically engineered to withstand the punishing nature of industrial workspaces, from the relentless pressure of heavy equipment to the wear from high foot and vehicle traffic. Whether dealing with forklifts in a warehouse or heavy machinery in a manufacturing facility, epoxy holds up where other materials fail.

- Resistant to Industrial Hazards: Spills, heat, and chemicals are daily threats in many industrial settings. Epoxy’s non-porous surface acts as a protective shield, preventing damage and deterioration from oils, chemicals, and even extreme temperatures. This feature also contributes to a safer work environment by reducing the risks of accidents and environmental hazards.

- Low Maintenance, High Efficiency: In a fast-paced industrial setting, downtime for floor maintenance is costly. Epoxy’s easy-to-clean surface minimizes the time and effort needed for upkeep. Less time spent cleaning means more time focusing on operations, and its longevity reduces the need for frequent repairs or replacements.

- Enhanced Safety and Customization: Safety is paramount in industrial facilities, and epoxy flooring can be customized to include anti-slip textures, hazard markings, and color-coded safety zones. This ensures not only durability but also compliance with safety regulations, reducing the risk of workplace accidents.

Applications for Industrial Epoxy Flooring

Industrial epoxy flooring isn’t a one-size-fits-all solution—it’s tailored to meet the specific challenges of different industrial environments. From chemical resistance to durability under heavy machinery, epoxy is versatile enough to perform across a variety of industries.

- High-Traffic Industrial Zones: In warehouses, distribution centers, and loading docks, epoxy flooring is crucial. These areas face constant movement from forklifts, heavy equipment, and large loads, but epoxy’s durability ensures the floor remains intact and functional, even under the heaviest demands.

- Chemical and Hazardous Environments: Industrial plants, laboratories, and automotive facilities often involve exposure to chemicals, oils, and other corrosive substances. Epoxy’s chemical-resistant surface prevents these materials from seeping into the concrete, protecting both the floor and the environment.

- Temperature-Sensitive Spaces: Cold storage facilities, food processing plants, and pharmaceutical labs require flooring that can handle extreme temperatures and fluctuating conditions. Epoxy remains stable in both freezing and hot environments, making it ideal for facilities with strict temperature controls.

- Safety-Critical Areas: In places where safety is paramount—such as manufacturing plants, service bays, or healthcare labs—epoxy floors can be customized with anti-slip textures and safety markers. These features help delineate safe walking areas, equipment zones, and hazard warnings, ensuring a safer workspace.

This approach emphasizes the tailored benefits of epoxy flooring for specific industrial needs, offering a more customized explanation for different environments.

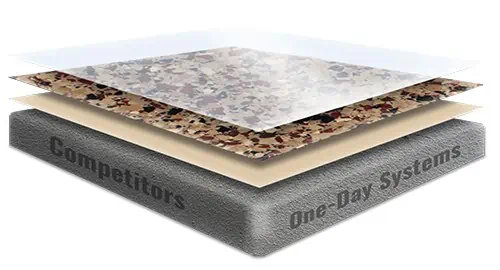

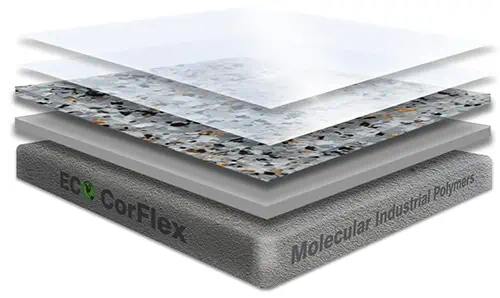

Our Two-Day Installation Process

We follow a detailed two-day installation process to ensure that your industrial epoxy floor stands the test of time. We begin with mechanical grinding to prep the surface and ensure proper adhesion of the first (primer) coat. Next, we apply a thick, slow-curing, moisture-mitigating epoxy primer as a moisture vapor barrier. It deeply penetrates and seals the concrete, preventing future moisture-related issues. Finally, we finish with application of two separate 100%-solids polyaspartic topcoats that provide chemical resistance, UV protection, and long-lasting strength.

View Our Epoxy-Polyurea-Polyaspartic Flooring Galleries

For more information on our epoxy-polyurea-polyaspartic floor coatings, or to schedule a free in-home estimate, give us a call or request a quote using the buttons below.

If you’re ready to upgrade your industrial facility’s flooring, call us or write us for a free consultation. Let us provide you with a flooring solution that works as hard as you do.