When it comes to garage floors in Maryland, proper concrete preparation is a game-changer. With weather that swings from humid and hot to cold and snowy, it’s crucial to get this step right for a durable, long-lasting finish. Let’s dive into what makes this process essential and how you can avoid common pitfalls.

Legal Considerations

One of the first things to consider is the local building codes in Maryland. These regulations are designed to ensure your garage floor meets safety and durability standards. Professional contractors are well-versed in these requirements, ensuring that every installation complies with local laws, which not only keeps you safe but also boosts your property value.

CSPs and Why They’re Important

Understanding Concrete Surface Profile (CSP) is vital. CSP measures the roughness of the concrete surface, which is critical for the epoxy primer coat to bond properly. The International Concrete Repair Institute ranks CSP from 1 (smooth as glass) to 10 (rough as gravel). For epoxy coatings, a CSP of at least 3 is needed. Achieving this often involves grinding, as it provides the ideal roughness (CSP 3 to 4) compared to other methods like low-pressure water jetting or acid etching, which can fall short, and sandblasting, which can be too aggressive.

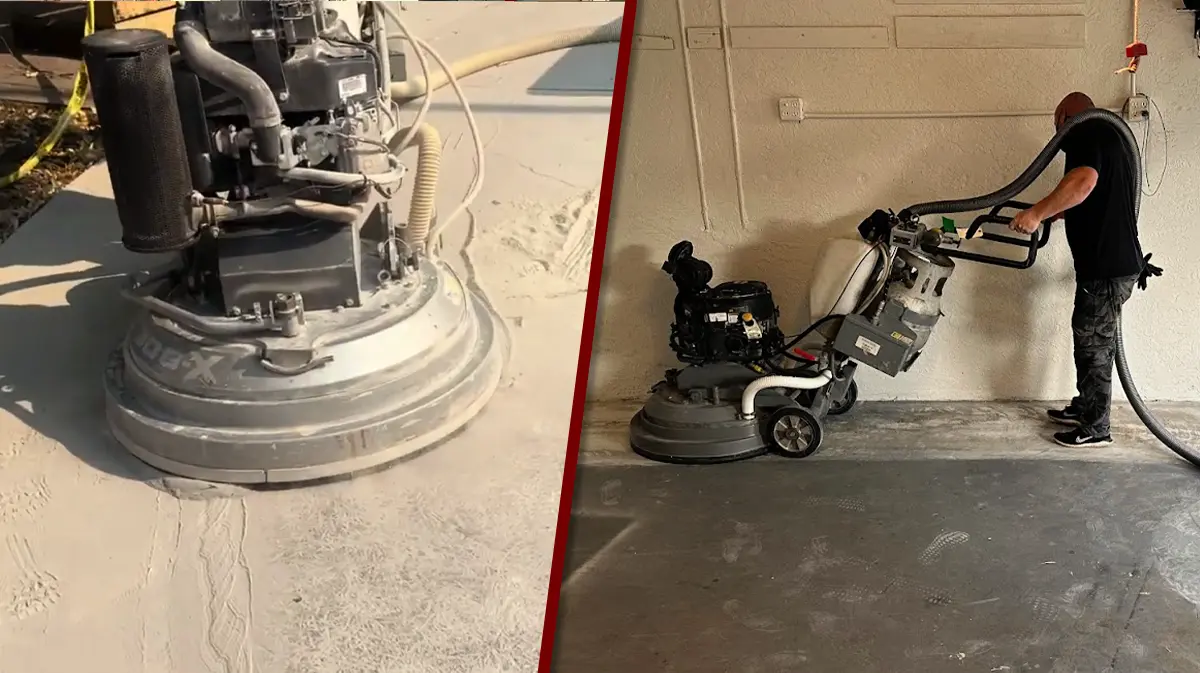

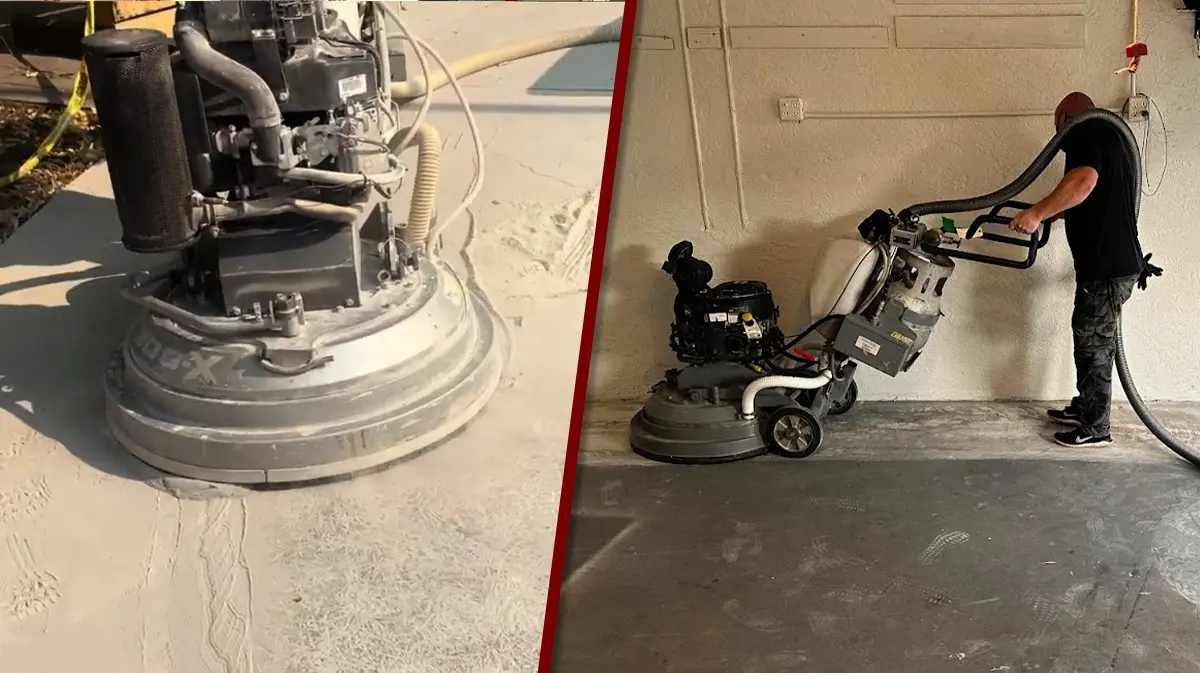

Tools of the Trade

Now, let’s talk about the tools. Propane grinders are the gold standard for achieving the perfect CSP. They are more powerful and efficient than electric grinders and, despite their higher initial cost, they save on labor and time. Additionally, propane grinders are safer for indoor use because they don’t require electricity, thus eliminating the risk of electrical hazards in damp conditions. Their near-zero exhaust emissions make them ideal for indoor environments.

Why do DIY projects often miss the mark? The main culprit is inadequate concrete preparation. The equipment needed to achieve the correct CSP is usually too expensive and specialized for DIY enthusiasts. Professional contractors bring the necessary tools and expertise to ensure the concrete is prepared correctly, resulting in a durable and high-quality epoxy coating.

Conclusion

In Maryland, where the climate can be particularly harsh on concrete surfaces, proper preparation is crucial. Investing in professional services for concrete preparation and epoxy coating ensures your garage floor can withstand the state’s challenging weather conditions. Properly prepared concrete provides a solid foundation for the epoxy primer coat, resulting in a durable and attractive finish.

Don’t cut corners — invest in professional concrete preparation to protect and enhance your garage floor for years to come.